VaxWell: A Robotic Vaccination System (2021.12)

A robot designed to save lives

Project Background

Project Objectives:

Design a robotic vaccination system that utilizes off-the-shelf, disposable syringes mounted on a kinematic arm and is capable of administering vaccines to over 90% of the adult population in the U.S.

Computational Resources Involved:

MATLAB. It was used to create the trajectory figures and simulations.

SOLIDWORKS. It was used to create the robot assembly and a studio view for our design.

Parts of the Design I was Responsible for:

Mainly responsible for robot system design and analysis.

Also contributed to CAD modeling and motion simulation.

Part 1 — Relevant Foundational Knowledge

Knowledge about Intramuscular (IM) Injection:

It is the injection method for most common vaccines. Usually with a dosage ≤ 1.0 mL.

For an adult, the needle length for full insertion depends on weight (up to 1.5 in. or 38 mm). The needle size is 22-25 gauge.

The injection site should be the triangular area of the deltoid muscle with a height of about 51 mm below shoulder height.

Ideally, a 90° injection angle (IA) wrt. surrounding skin should be maintained. However, as arm tissue is soft and has variable curvature, a slightly off IA is acceptable.

Knowledge about Forces of Interest:

Assume a 51mm, 25-gauge needle, and a 1 mL syringe is used.

Approximated maximum needle penetration force for soft tissue: 2.644 N.

Approximated maximum needle penetration force for bone: 119.303 N.

Approximated initiating force on the plunger for drug delivery (95%CI): (0.61, 1.68).

Approximated sustained force on the plunger for drug delivery (95%CI): (0.00, 0.25).

Basic Ergonomics Data:

All data are obtained from the formula SAE database for North America Region. All models are in a standard sitting position.

The shoulder heights (Parameter 10) of 5th percentile U.S. adult females are 505 mm, or SH5F = 505 mm.

The shoulder heights (Parameter 10) of 95th percentile U.S. adult males are 645 mm, or SH95M = 645 mm.

Injection site height (di): dimin = SH5F -51= 454 mm, dimax = SH95M -51= 594 mm.

Step 2 — Defining Robot Mode of Operation (MOP) & Model Parameters

To achieve the design goal, a three-DOF robot arm was designed with two rotational joints and one prismatic joint. Two boundary MOPs were defined for the robot:

The robot should be able to perform IM injections to the 5th percentile U.S. females when the arm was at the fully horizontal state (both thetas are at 0).

The robot should be able to perform IM injections to the 95th percentile U.S. males when the arm was at the highest workable state (theta1 = 90 deg).

With the boundary MOPs, the fixed model parameters were determined, as shown in the figures. Meanwhile, it would be worth noting that all three joint variables would have variable values during the robot movement.

After fixed parameters were defined, two actual MOP cases were established.

For the first MOP or case A, the robot moved from an initial position to inject the vaccine into the 5th percentile of U.S. adult females.

For the second MOP or case B, the robot moved from IP to inject the vaccine into the 95th percentile of U.S. adult males.

Step 3 — Designing & Simulating the Joint Trajectories

The trajectories of each joint were designed and specified to ensure a smooth motion of the robot. The joint trajectories were simulated in MATLAB. To view animated joint motions, please refer to the video presentation at the end of this page.

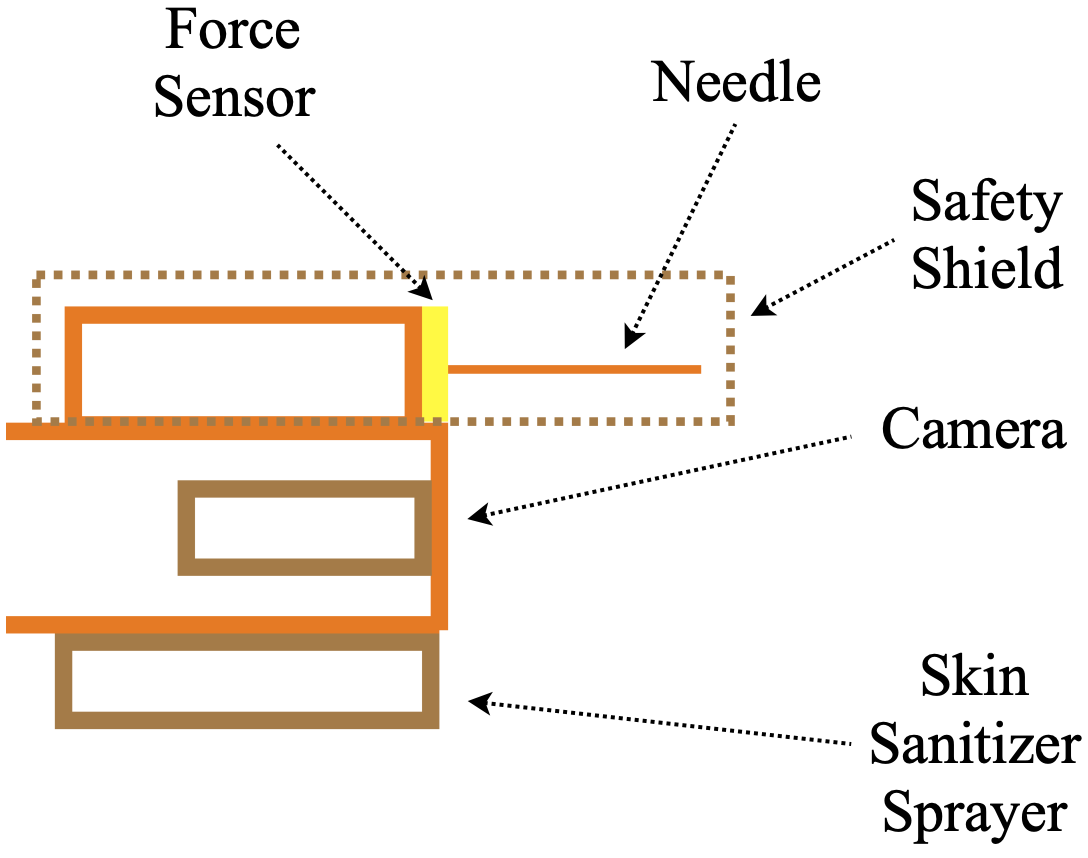

Step 4 — CAD Modeling & Safety Considerations

There was a three-level safety assurance system designed for the arm:

Needle entry depth was monitored after the force sensor picked up the initial spike in forces received by the needle. The final needle entry depth (controlled by the prismatic joint movement) was set equal to the needle length.

When the force sensor picked up a force greater than 1.5 times the normal sustained force for soft tissue penetration, the arm would shut down, and medical personnel assistance would be requested.

The force output of the prismatic joint was always controlled (by the motor algorithm and sizing) below 0.5 times the normal sustained force for bone penetration.

Want to discover even more?

You can download the full project report from the link below, or you may listen to our recorded presentation.