Additional Project Collection

Fewer words, but equally fun

Programmable Modeling of Lamp Shades (2022)

Model complex structures with the use of codes only. New designs can be created by changing a line of codes.

Computational Resources Involved:

openSCAD. It was used to turn written codes into 3D structures.

Siemens NX. It was used to create a studio view for our design.

Physical Resources Involved:

Ultimaker 3D Printer.

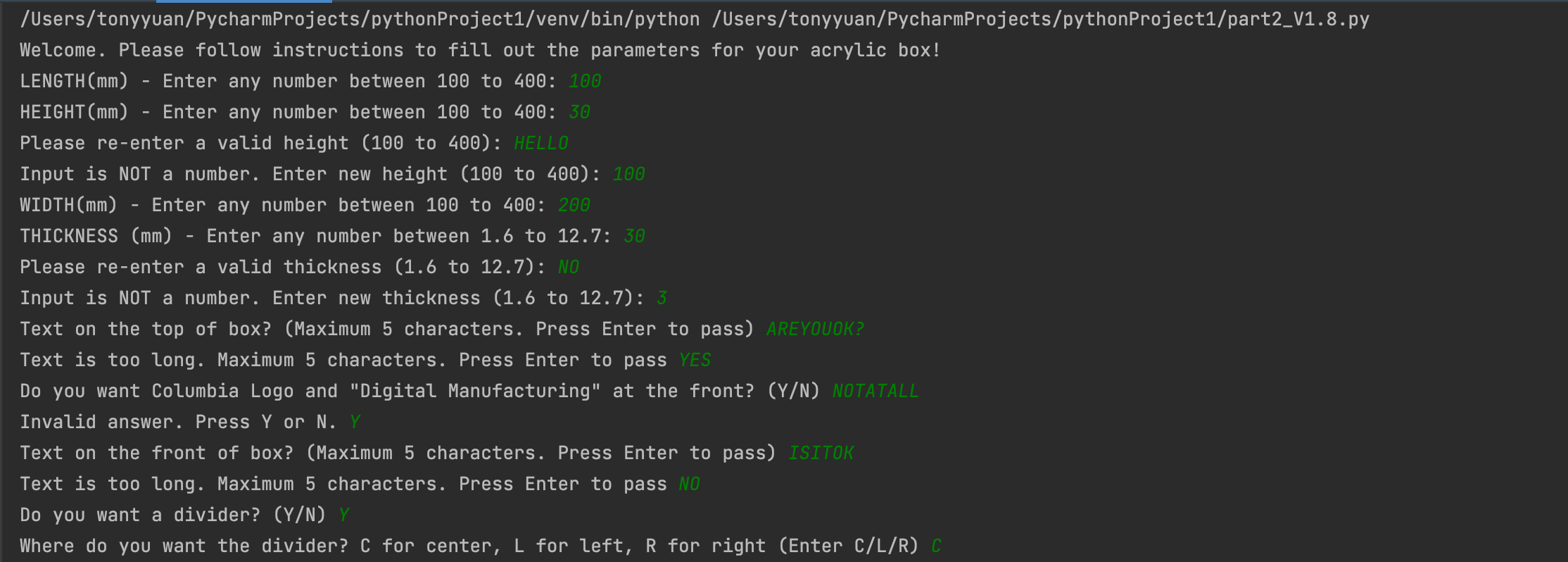

Programmable Laser Cut Box (2022)

Produce customized storage boxes by interacting with a self-written Python program.

Computational Resources Involved:

Python. It was used to turn written user input into SVG codes.

Physical Resources Involved:

Laser cutter. It was used to read SVG files and cut/engrave as instructed.

An Underwater Robot Designed for The Scallop Farming Industry (2020)

The preliminary system design and simple CAD modeling of a remotely self-sustainable waterproof robot for scallop sampling.

Computational Resources Involved:

Siemens NX. It was used for modeling, creating multi-level assemblies, and drafting.

MATLAB. It was used to generate figures that supported the design.

Part of the Project Mainly Responsible for:

Robot mode of operation (daily and inter-day)

Robot energy generation system design

Power and energy equilibrium verification

Part of the CAD modeling

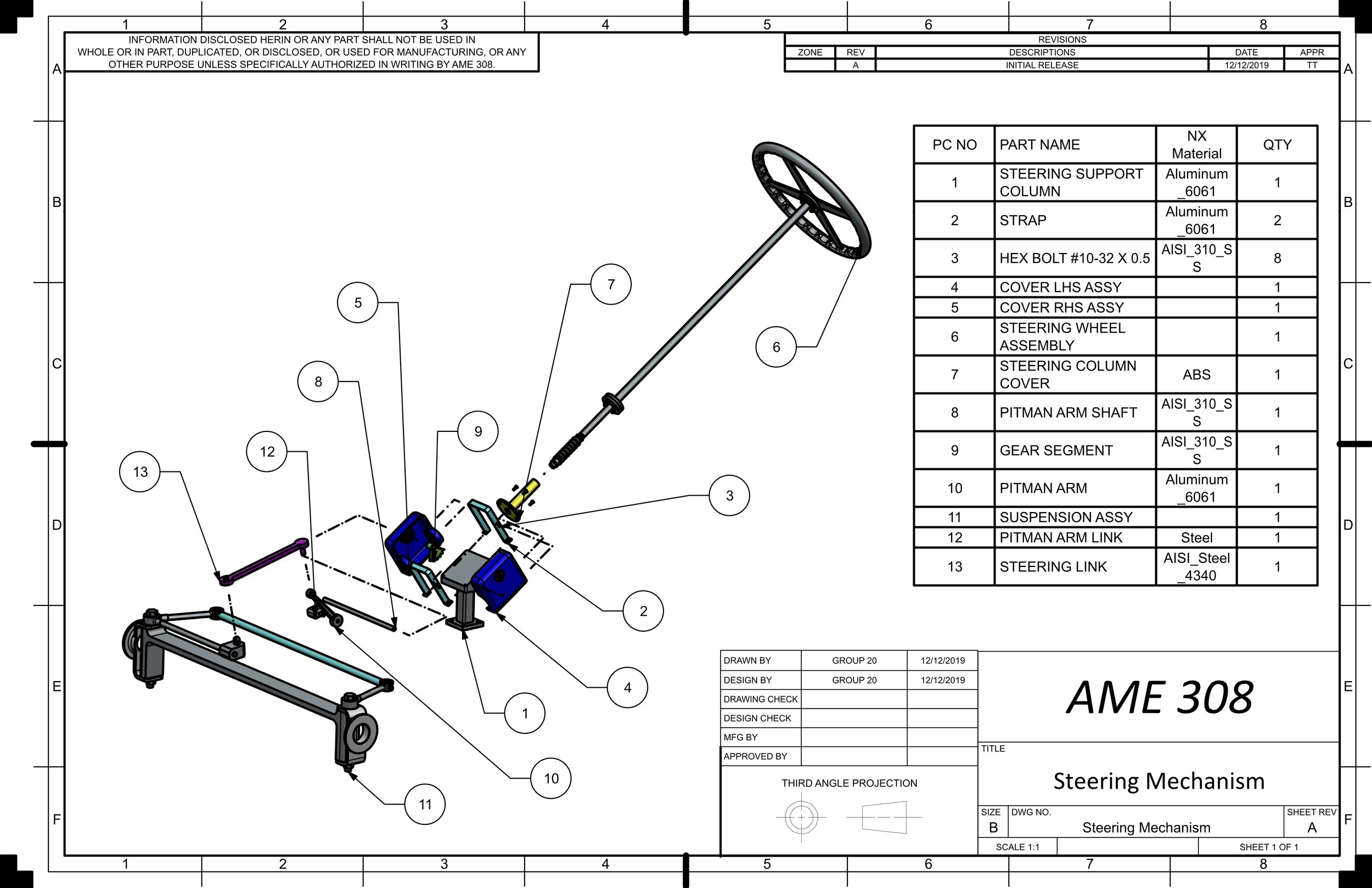

The CAD Design of an Electric Cart (2019)

A new look for the street of USC.

Computational Resources Involved:

Siemens NX. It was used for modeling, creating multi-level assemblies, drafting (dimensional/GD&T/exploaded views with BOM), and motion simulation (steering system).

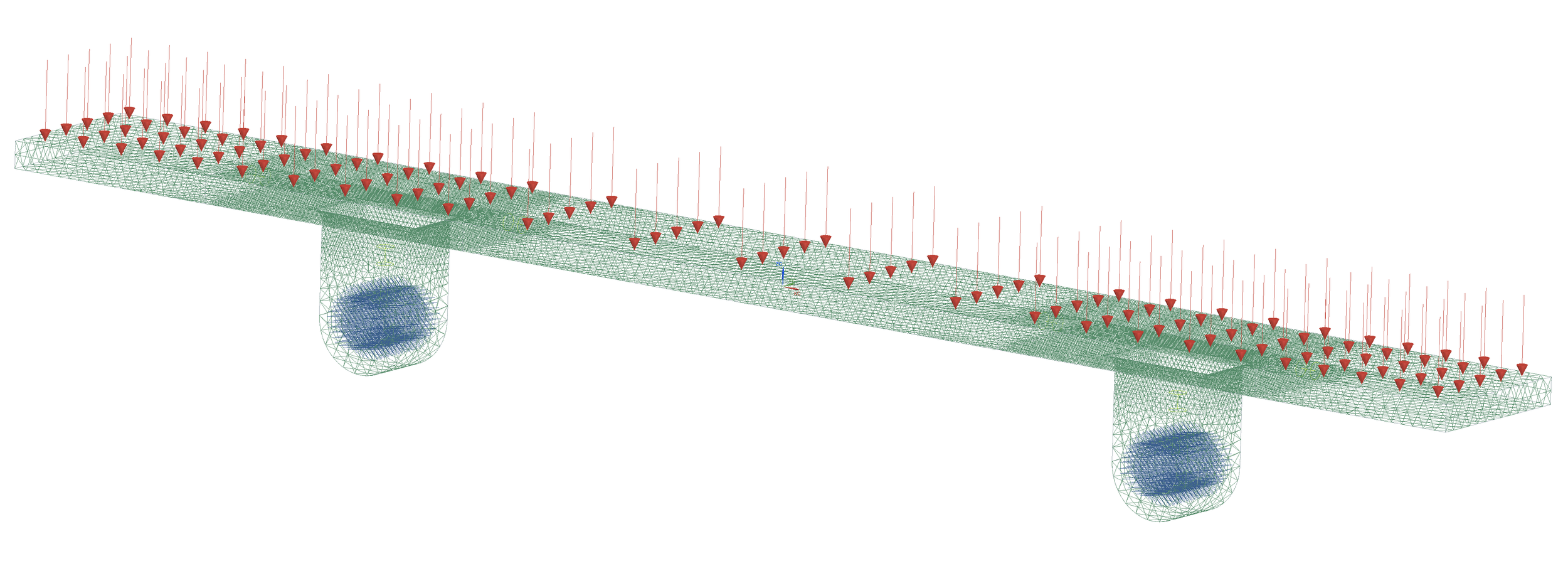

Samples of Training on Siemens NX (2019)

Supplemental work samples about complex drafting and FEA.

Computational Resources Involved:

Siemens NX. The use of the “split body” tool allowed mesh of different sizes to exist within an originally united body. This could help find convergence in a stress-concentrated area at a much faster speed.

The Design & Launch of a Water Rocket (2019)

The transformation from a water bottle to a rocket with a parachute.

Computational Resources Involved:

MATLAB. It was used to establish a mathematical model to determine the rocket's optimal water volume and the theoretical height reachable by the rocket. The input parameters included the rocket's geometries and weight, the water's mechanical properties, and the temperature at the launch site.

Siemens NX. It was used to verify the hypothesis that stress concentration due to the use of high-strength adhesives was the cause of the rocket explosion.

Physical Resources Involved:

3D Printer. It was used to produce custom-built nose cones and fins for our rocket.

Particularly interested in some of them?

You can contact me through the link below! I am happy to provide more information.